MJM Printing

Multijet Modeling Technology

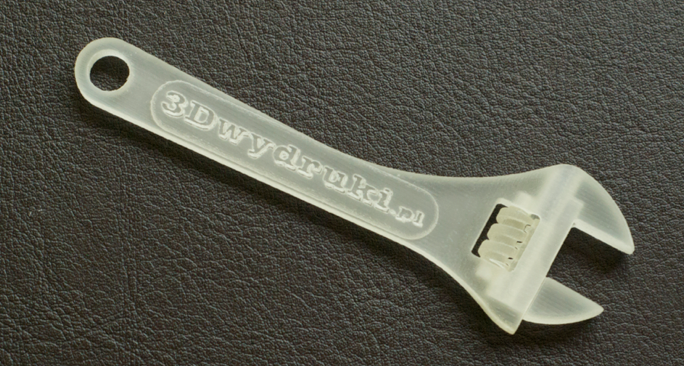

This technology is used to create precise models. Printed items are made of the highest quality, where the horizontal thickness is .032 mm. Items are printed while maintaining the smallest detail (accuracy of 0.025 - 0.05 mm), and have an extremely smooth surface, thanks to the time of printing, while two materials - building material is a photopolymer cured using UV light and the supporting material is the wax.

Based on prototypes created in technology MJM we create silicone mold castings or entire series of products, models of mobile (resulting in one print), functional prototypes. Models are durable and resistant to temperatures of up to approximately 80 ° C, they may be subject to further treatment such as painting, gluing, grinding and drilling.

.jpg)