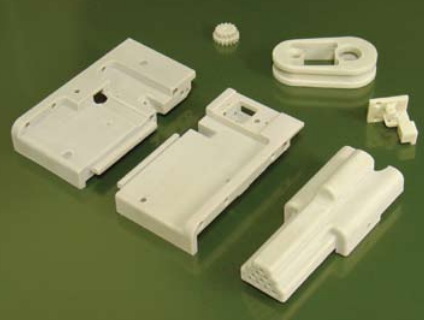

SLS Printing

SLS Technology

Selective laser sintering is a method that involves printing by assembling the materials in powder form, layer by layer, which occurs thanks to the action of the laser beam on the powder surface.

The powder layer with a thickness of 0.02 - 0.06 mm is beeing spread on the base plate, at the points with well-defined coordinate system, the laser beam is beeing directed. His energy causes the individual powder particles merge together to form a layer of solid material. In the construction of several layers of course the energy of the laser beam leads to connect to the grain of the film with each other and with the previous layer, which now serves as the substrate. The process is repeated until the construction of the whole subject. To create the object, depending on the complexity of the shape may be further additions were, auxiliary components (generated by the internal program of the device) that support the further layer. The resulting object is subjected to a finishing treatment (locksmith and / or machining and grinding) leads mainly to remove the remaining traces of the supports. Sintered components can also be treated by electrodischarge, machining, grinding.

The described technique allows you to make complex parts of external and internal (eg, cooling channels in injection molds).